Drum

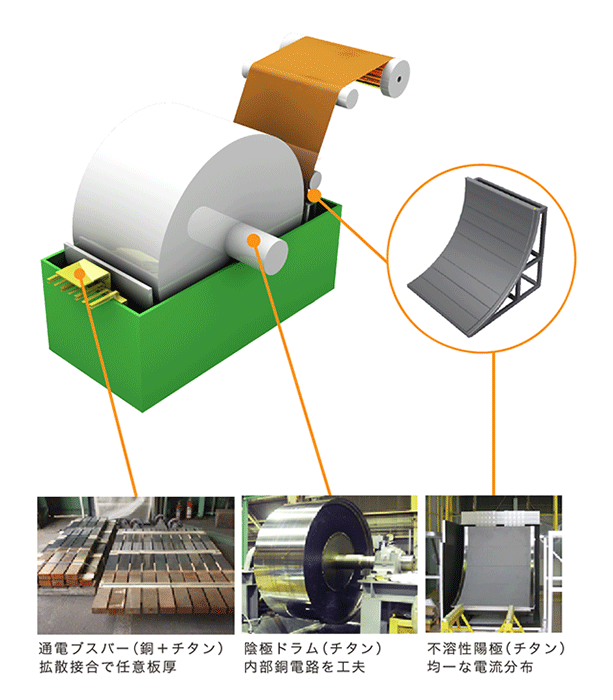

Electrolytic Copper Foil Manufacturing Facilities

The demand for electrolytic copper foil is rising along with its use in lithium-ion batteries and printed circuit/wiring boards. Our company manufactures cathode drums (titanium), anodes (titanium) and bus bars (copper), at the heart of such manufacturing facilities.

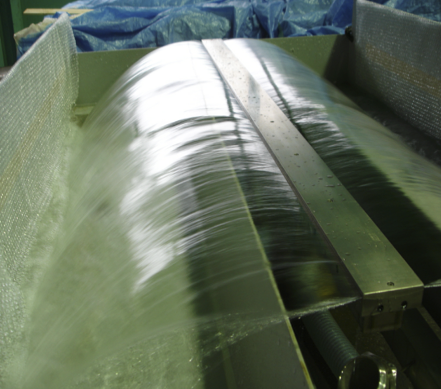

Cathode Drum

This is our company’s original design for evening out current distributions.

Advanced processing technologies enable the skin welding to have a structure similar to the base material.

These original technologies and devices are patented.

We can also answer to a variety of sizes from the test drum at approx. φ600 to the large-diameter drum at φ3000.

We answer to all kinds of needs, from new product manufacturing to rewinding, remodeling and repair.

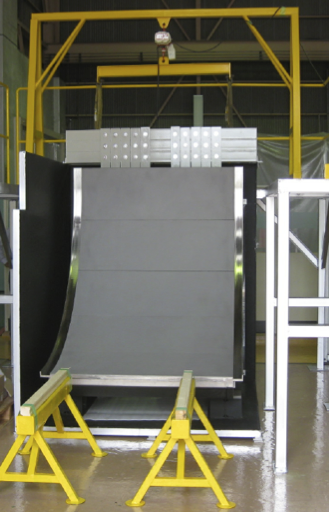

Anode Frame

These can be individually designed to user needs, in response to electric current and electrolysis tank space.

Electrodes are generally manufactured in a single sheet, but can also be divided into separate pieces for ease of removal and installation.

For electrode materials, plate thickness can be selected to even out the current distribution.

The electrode plane has been designed smooth, with few projections, so as not to influence electrolyte flow.

In terms of electricity conduction, bus bar connections have been widely dispersed on the back of the electrode to even out the current distribution.

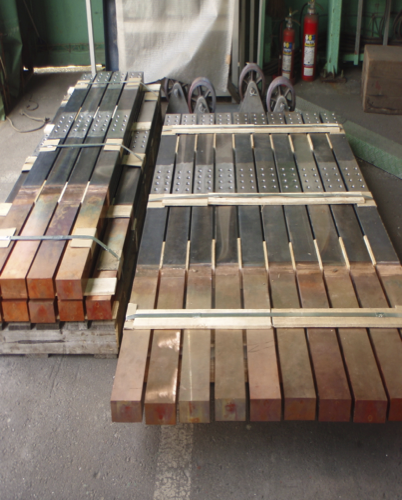

Bus Bar

These are for use in electric circuits that require corrosion resistance in the copper core, such as electolyzer, metal plating and environmental facilities.

The plate or bar-shaped copper core base is covered and diffusion-welded with corrosion-resistant materials like titanium.

Manifold

These can be individually designed based on the user’s operating conditions, flow quantity and velocity, and space inside the electrolysis tank.

※The current distribution of electrodes and standardized operating conditions for electrolytes will be indispensable for future manufacturing of high-quality foils.