Gravi-Merge Blender™ (Silo Blender)

In addition to its superb blending performance, the Gravi-Merge Blender’s simple structure also helps cut down its running costs.

We can also conduct blending tests with the Gravi-Merge Blender at test plants.

Our company has recently acquired this knowhow to develop out into the world, so please let us help in any way we can!

Some examples of Gravi-Merge Blender™ Usage

1. Standardizing Lots

Variations within the same lot that arise in special manufacturing facilities cannot be avoided. Please use this blender for quick, reliable blending and for standardization of your lots.

2. Managing Transitional Material

Please use this product for handling transitional material generated when switching grades at resin manufacturing plants and other facilities. Being able to effectively use transitional materials will help to greatly cut down costs. Our company’s past records include use in managing not only MI values but molecular weight as well.

3. Blending Different Kinds of Pellets

The Gravi-Merge™ Blender allows for the blending of products in small ratios, a process heretofore difficult with the conventional blender. Reliable blending is possible even at a weight ratio of 90:10.

4. Blending Different MI Values

When blending products with different MI values, it is necessary to obtain blending results close to the theoretically-derived logarithmic mean MI value – this blender responds to this need. It can further be used to reliably blend products with highly different MI values.

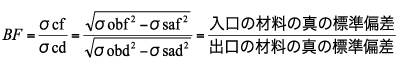

Blending Performance

The Gravi-Merge™ Blender’s performance is quantified by a term called Blend Factor (BF). Blend factor is the ratio of the standard deviation of the feed to the blender (σf) divided by the standard deviation of the discharge (σd).

Definition of BF

σob:The apparent standard deviation as calculated from a series of samples collected from the inlet and outlet. A value not corrected for sampling or measurement error

σsa:Standard deviation from sampling and analysis errors that arise when measuring σob

σc:True standard deviation corrected for sampling and analysis errors

f:Blender inlet

d: Blender outlet

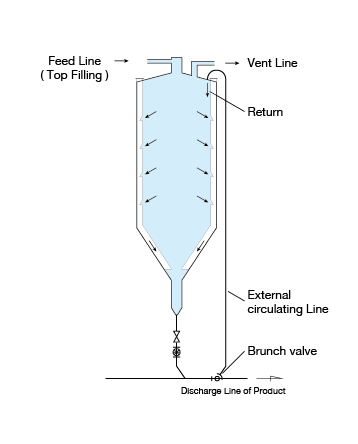

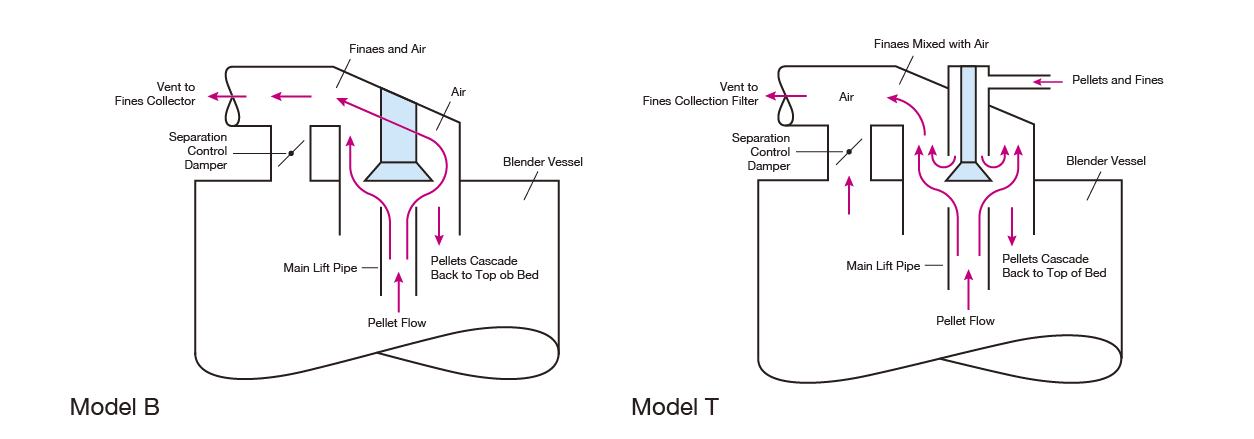

Model T

・Top filling

・Internal recirculation

・Can recirculate/blend during feeding

⇒Improved blending performance & reduced blend time

・Use of 2 blowers for feeding and recirculation

・Built-in fines separator can also be installed (option). This eliminates the need for a separate cleaning system.

・Test case: BF for 3 inventory turns=22.0

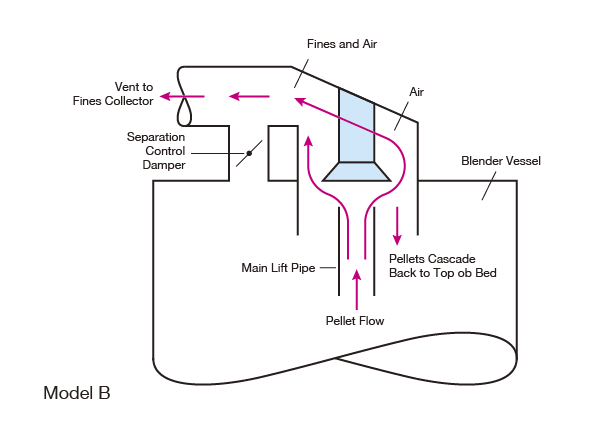

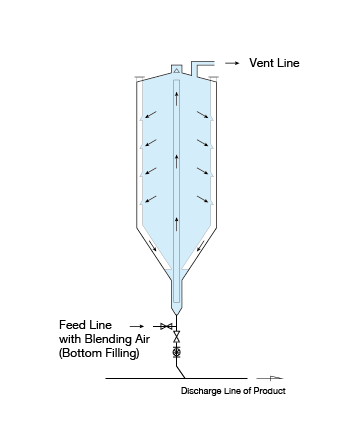

Model B

・Bottom filling

・Internal recirculation

・Can recirculate/blend during feeding

⇒Improved blending performance & shortened blend time

・Only uses 1 blower, and can recirculate with the blower for feeding

⇒Reduced equipment costs

However, because one device is used for both pneumatic conveying of the feed and the blower for blending, some restrictions apply to its application.

・Built-in fines separator can also be installed (option). This eliminates the need for a separate cleaning system.

・Test case: BF in 3 inventory turns=22.0

Model G

・Top filling

・Allows external recirculation where necessary

・No central lift pipe

⇒Simple structure

⇒Suited for large-scale silos

・Generally for once-through operation

⇒External recirculation can be used when high-level blending performance is required

・Higher blend performance possible with the same number of inventory turns in comparison to Models T and B

・Test case:BF in 3 inventory turns=40.0 Once-through BF=2.4

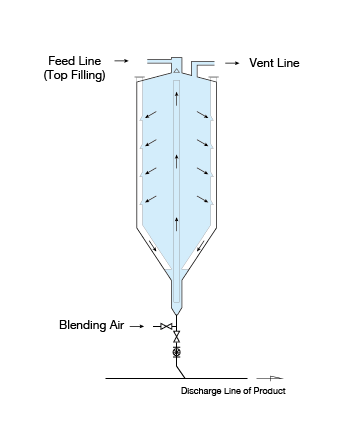

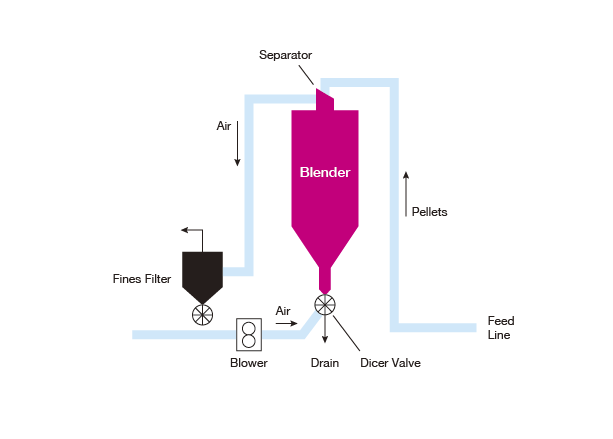

Built-in Fines Separator

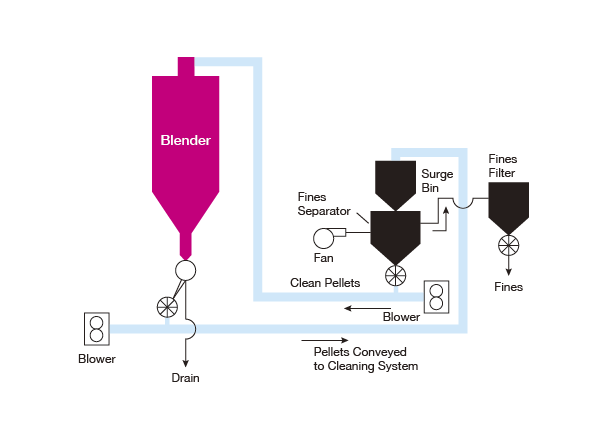

A fines separator option can be installed on the Gravi-Merge™ Blender. In the conventional system (Fig. 1 below), the fines separator was attached separately, however, this caused a need not only for excessive machinery, but also for excessive power.

In the Models T and B Gravi-Merge™ Blenders, a built-in separator can be installed to separate fines during filling and blending. This allows for the cut-down of 2 rotary feeders, 1 blower, 1 fan, 1 surge bin and the conventional fines separator. In one case, there was even a power reduction of 170BHP.

Gravi-Merge™ Blender with built-in fines separator

The built-in fines separator can be installed on both the Model B (bottom filling) and Model T (top filling) blenders. Both are simple, require no excessive machinery, and are cost effective due to the reduction in power consumption.

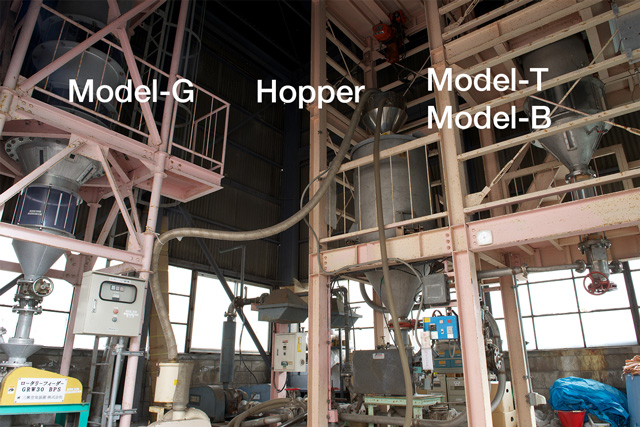

Blend Test Device

At our company, we also provide a 1m3 test device to answer to our customers’ needs. This will not only enable you to confirm the blender’s superb blending performance, but we can also propose various applications possible only with this blender. So please try using this test device!

Test Device Specifications

1. Blender

Capacity: 0.93m3

2. Hopper

Capacity: 1.15m3

3. Roots Blower

Air flow: 2〜4.3m3

Suction pressure: −250mmAq

Discharge pressure: 2500mmAq

Electric motor: 50Hz/5.5kW(200V/4P)

4. Rotary Valve

Transport Capacity: 50〜500kg/hr(VVVF Control)

Electric Motor: 50Hz/0.75kW(200V/4P)

5.Bag Filter

Capacity: 8m3/分

Air Pressure: 7kg/cm3

6.Load Cell(4-point mounting)

Weighing: 0〜500kg

Tare weight: 160kg